Content Menu

● Manufacturing and Processing Overview

● Taste, Texture, and Consumer Perception

● Applications Across Industries

● Regulatory Landscape and Labeling

● Alternative Sweetener Options and Blends

● Strategic Opportunities for Chinese Manufacturers

● Quality, Safety, and Sustainability Considerations

● Practical Guidance for Collaboration

● FAQ

>> 1. What is the primary sweetener used in Splenda products?

>> 2. Why are bulking agents used with sucralose in many formulations?

>> 3. How does sucralose behave under heat and cooking?

>> 4. Are there regulatory considerations when using Splenda or sucralose in export products?

>> 5. What advantages do blended Sweetener systems offer to manufacturers?

This article provides a comprehensive look at Splenda sweetener—its origins, key ingredients, manufacturing pathways, and how such high-intensity Sweeteners sit within the broader landscape of health-focused ingredients used by food, beverage, and healthcare manufacturers. For overseas partners and contract manufacturers, understanding the composition, processing, and regulatory considerations of sucralose-based sweeteners informs better product development, sourcing decisions, and OEM/ODM collaborations. The discussion also situates Splenda within the larger ecosystem of Sweetener solutions, including natural sweeteners, functional polyols, and dietary fibers that many modern formulations rely on to achieve balanced taste, texture, and health outcomes.

Splenda is widely recognized for its sucralose-based sweetener products. Sucralose is a high-intensity Sweetener that delivers sweetness at magnitudes far greater than sucrose, enabling low- or zero-calorie formulations. To translate the intense sweetness into consumer-friendly formats, many Splenda products pair sucralose with bulking agents such as dextrose or maltodextrin. This pairing helps achieve familiar sugar-like texture, scoop-ability, and accurate serving sizes in packets, cups, or granulated forms, which is essential for both beverages and solid foods. The Splenda brand emphasizes consistency, heat stability, and reliable solubility, making it a common choice for products ranging from tabletop sweeteners to bake-ready ingredients. For manufacturers, this model illustrates how a single high-intensity Sweetener can be operationalized across multiple formats through careful formulation and quality control.

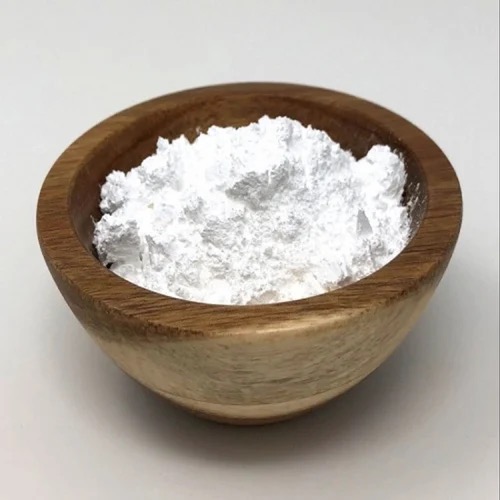

- Sucralose: The core active sweetening agent, a chlorinated derivative of sucrose that is hundreds of times sweeter than sugar. It provides sweetness with negligible caloric impact and excellent heat stability in many formulations.

- Bulking Agents: Dextrose, maltodextrin, or other carriers are employed to create granulated or packet forms that users can measure and mix, ensuring that sweetness levels are consistent with consumer expectations for "sugar-like" texture and volume.

- Processing Aids and Additives: Depending on the product line, anti-caking agents, stabilizers, or minor processing aids may be included to improve pourability, mixability, and shelf-life. These components are selected to complement sucralose's sweetness while maintaining product safety and label accuracy.

- Raw material sourcing: Sucralose is produced through selective chlorination of sucrose, followed by purification steps to achieve high purity and stability. Carrier materials are sourced to support the intended product format (powder, tablets, or blended liquids).

- Formulation strategy: The bulk sweetener is formulated by integrating sucralose with carriers to deliver target sweetness intensity, mouthfeel, and dissolution characteristics. The formulation must align with the intended use—tablets for supplements, granules for beverages, or powders for cooking and baking.

- Quality control and regulatory compliance: Extensive QC ensures ingredient purity, microbial safety, and batch-to-batch consistency. Labeling must accurately reflect all ingredients and potential allergens in accordance with regional regulatory regimes.

- Sweetness profile: Sucralose provides a clean sweetness with minimal aftertaste for many users, but individual taste perceptions can vary depending on the formulation and blending ingredients.

- Mouthfeel and texture: The choice of bulking agents influences the perceived texture, mouthfeel, and solubility, which are critical for consumer satisfaction in both hot and cold applications.

- Aftertaste considerations: In some blends, the residual aftertaste from certain carriers may be mitigated through taste-modifying excipients, balancing the overall sweetness experience.

- Food and beverages: Low- to zero-calorie drinks and foods benefit from high-intensity Sweeteners that preserve flavor while reducing calories, enabling product lines targeted at health-conscious consumers.

- Healthcare and dietary supplements: Tablets and powders require precise sweetness and stable performance during processing, packaging, and shelf-life. Sucralose-based blends can be tailored to maintain sweetness across varying storage conditions.

- Bakery and confectionery: Heat stability and compatibility with other ingredients enable successful integration into baked goods and sweet treats, where texture and sweetness must remain consistent under heat exposure.

- Global variations: Different markets impose distinct requirements for labeling, disclosure of sweeteners, and permissible daily intake references. Compliance is essential for successful export and sustained partnerships.

- Clean-label trends: Some manufacturers prefer blends that reduce artificial carriers or highlight natural sweeteners to align with consumer demand for transparent ingredient lists.

- Documentation and traceability: For OEM/ODM collaborations, robust documentation on ingredient provenance, processing steps, and quality control enhances trust with overseas clients and regulators.

- Natural sweeteners: Stevia and monk fruit extracts offer natural sweetness and flavor profiles but may introduce aftertaste that needs balancing in blends.

- Other high-intensity sweeteners: Saccharin, aspartame, and acesulfame potassium provide different sweetness curves and regulatory considerations, making them more suitable for specific product types or market preferences.

- Polyols and dietary fibers: Functional polyols (e.g., sorbitol, xylitol) and fibers can be combined with high-intensity sweeteners to modulate texture, caloric impact, and glycemic response, providing innovative solutions for health-focused products.

- Blended-sweetener development: Your factory, with capabilities in natural sweeteners, functional polyols, and dietary fibers, can design customized blended-sweetener systems tailored for international clients. This aligns with demand for Sweetener solutions that balance taste, texture, and health benefits.

- OEM/ODM services: Tablet production, powder blends, and beverage sweetening are viable service lines that meet diverse regulatory and quality standards across overseas markets.

- Ingredient traceability and sustainability: Emphasizing sustainable sourcing, transparent supply chains, and quality assurance can differentiate your offerings in a crowded market and support premium positioning for Sweetener solutions.

- Shelf-life and storage: Formulations must maintain sweetness stability, flavor integrity, and physical stability under varying temperatures and humidity conditions.

- Allergen management: Clear labeling for potential cross-contact with common allergens is essential in global markets.

- Sustainability: Adoption of eco-friendly packaging, responsible sourcing, and transparent manufacturing practices resonates with international buyers and supports long-term partnerships.

- Define target market and format: Clarify whether the project focuses on beverages, baked goods, or supplements, and specify the desired format (granulated, powder, or tablet).

- Align on regulatory strategy: Collaborate with regulatory experts to tailor ingredient declarations, labeling, and compliant usage for each target country or region.

- Establish QA expectations: Outline testing requirements, acceptance criteria, and routine audits to ensure consistent quality across production runs.

- Plan for scale-up: Prepare a phased plan from pilot blends to full-scale production, including timelines, cost implications, and risk management.

The world of Sweetener solutions sits at the intersection of science, consumer preferences, and regulatory nuance. Splenda-style sucralose-based Sweeteners illustrate how high-intensity sweetening can be married with carrier systems to deliver sugar-like experiences in a zero- or low-calorie format. For health-focused manufacturers in China and abroad, there is a meaningful opportunity to translate this model into blended-Sweetener systems that combine natural options with functional polyols and dietary fibers. Such blended-Sweetener solutions can support OEM/ODM projects across beverages, baked goods, and dietary supplements while meeting diverse regulatory requirements and evolving consumer expectations.

The primary sweetener is sucralose, a high-intensity, zero- or very-low-calorie sweetener derived from sugar. It provides sweetness hundreds of times greater than sucrose and is commonly combined with bulking agents to achieve practical formats. The sucralose core is responsible for the intense sweetness in many Splenda variants.[4][10]

Bulking agents such as dextrose or maltodextrin provide texture, volume, and a measurable form for consumer use, enabling granulated and packet formats that resemble sugar in weight and handling. They help convert a potent sweetener into consumer-friendly products.[11][4]

Sucralose generally demonstrates good heat stability, allowing use in many baked goods and hot beverages, though performance can depend on the complete formulation and co-ingredients. Testing is advised for specific recipes and products.[5][4]

Yes, regulatory requirements include accurate ingredient declarations, labeling, and adherence to acceptable daily intake guidelines, which vary by country/region. Consultation with local regulatory experts is recommended for each target market.[10][5]

Blended systems combining natural sweeteners, polyols, and dietary fibers can improve taste profiles, mouthfeel, texture, and nutritional positioning, while enabling compliance with clean-label trends and regulatory expectations across multiple markets. This approach aligns with OEM/ODM capabilities to deliver customized solutions for overseas clients.

[1](https://www.splenda.com/faqs/how-is-splenda-stevia-grown/)

[2](https://www.studocu.com/en-us/document/james-madison-university/concepts-of-organic-chemistry-laboratory/isolation-of-sucralose-from-splenda/12077423)

[3](https://easybuyingredients.com/blog/sucralose-production-demystified-from-raw-materials-to-manufacturing-process/)

[4](https://www.splenda.com/faqs/what-is-splenda-sucralose-and-how-is-it-made/)

[5](https://www.sciencedirect.com/topics/food-science/sucralose)

[6](https://processengr.com/project/sucralose-sweetener-manufacturing-plant-preliminary-process-design/)

[7](https://ginhong.com/how-are-artificial-sweeteners/)

[8](https://pmc.ncbi.nlm.nih.gov/articles/PMC3856475/)

[9](https://en.wikipedia.org/wiki/Sucralose)

[10](https://www.splenda.com/product/splenda-sweetener-packets/)

[11](https://www.splenda.com/product/splenda-granulated-sweetener/)

Top Nutritional Supplement Manufacturers And Suppliers in Brazil

Top Nutritional Supplement Manufacturers And Suppliers in Belgium

Top Nutritional Supplement Manufacturers And Suppliers in Austria

Top Nutritional Supplement Manufacturers And Suppliers in Australia

Top Nutritional Supplement Manufacturers And Suppliers in Argentina