Views: 222 Author: Sara Publish Time: 2025-11-17 Origin: Site

Content Menu

● Context and Market Significance

● Feedstock Selection and Raw Materials

● Chemical Transformation and Reaction Pathways

● Formulation and Functional Blends

● Quality Assurance and Regulatory Compliance

● Packaging, Storage, and Stability

● Applications Across Industries

● Sustainability and Innovation

● Safety, Transparency, and Consumer Trust

● Practical Considerations for Overseas Manufacturers

● Case Study: OEM/ODM Collaboration in Action

● Continuous Improvement and Quality Culture

● Toward a Global, Sustainable Sweetener Ecosystem

● FAQ

>> 1. What is the basic idea behind Splenda-style Sweetener production?

>> 2. How are impurities controlled during manufacturing?

>> 3. Why is sweetness potency important in formulation?

>> 4. What regulatory considerations matter for international markets?

>> 5. Can Sweetener blends be customized for OEM/ODM projects?

This article explains the cradle-to-grave process of how a modern Sweetener like Splenda is manufactured, including feedstock sourcing, chemical modification, purification, and final formulation. The discussion also highlights how such Sweetener ingredients fit into contemporary food, beverage, and healthcare applications, with emphasis on safety, quality, and regulatory compliance. For manufacturers and brands worldwide, understanding these steps helps optimize product development and ensure a stable supply of high-quality Sweetener ingredients. The goal is to provide a comprehensive, business-friendly view of Sweetener production that supports OEM/ODM partnerships and international supply chains.

Sweetener ingredients play a pivotal role in reducing sugar content while preserving taste, texture, and consumer acceptance. The global demand for low- or zero-calorie Sweetener options continues to rise as brands pursue healthier formulations and regulatory bodies push for clearer labeling and safety assurances. A clear understanding of how Splenda-like Sweeteners are produced enables contract manufacturers, ingredient suppliers, and brand owners to align on quality standards, cost structures, and timeline expectations for new product launches.

Sweeteners span several categories, each with distinct chemistry, sensory profiles, and regulatory considerations. Broadly, these categories include artificial Sweeteners, sugar alcohols (polyols), and natural Sweeteners. Within the artificial Sweetener domain, chlorinated or otherwise modified sugar derivatives often deliver high-intensity sweetness with minimal caloric contribution. Sugar alcohols provide bulk and sweetness with partial caloric content and specific functional properties. Natural Sweeteners, derived from plant sources, offer clean-label appeal but may require different processing and pricing considerations. This article uses the Splenda family as a representative case to illustrate the key steps, challenges, and opportunities involved in modern Sweetener production, formulation, and application.

The production of high-quality Sweetener ingredients begins with careful selection of feedstocks. For many synthetic or modified Sweeteners, raw materials come from refined sugar streams or starch-derived glucose, chosen for their purity, supply reliability, and compatibility with downstream processing. Contaminants and trace impurities in feedstock can have cascading effects on yield, impurity profiles, and sensory attributes, so rigorous supplier qualification and incoming quality checks are essential. In a well-managed Sweetener operation, supply chain resilience is built through diversified sourcing, inventory buffering, and proactive risk assessment to minimize production disruptions and maintain consistent product performance.

A core feature of many high-intensity Sweeteners is the chemical transformation of a carbohydrate scaffold into a molecule with substantially altered sweetness properties. In the Splenda family, the transformation involves selective chemical modifications that dramatically amplify perceived sweetness while maintaining a clean aftertaste and stable performance across product matrices. The specifics of reaction pathways are often guarded as trade secrets, but the underlying principles include selective functional group modification, protection-deprotection strategies, and controlled reaction kinetics to minimize byproducts. Safety and environmental considerations guide solvent selection, catalyst use, and reaction monitoring, ensuring operations stay within regulatory and sustainability boundaries.

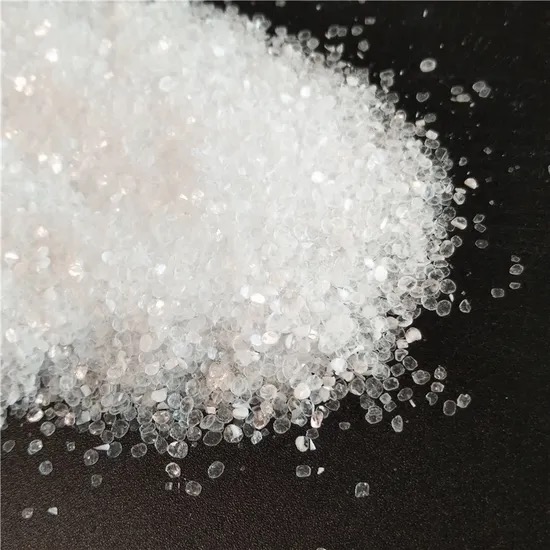

Following chemical transformation, purification is essential to remove residual reagents, byproducts, and trace impurities. Purification strategies may involve crystallization, filtration, drying, and solvent exchange, as well as advanced techniques like adsorption or chromatography in certain cases. The objective is to achieve a highly pure Sweetener suitable for broad food, beverage, and healthcare applications, while maintaining process efficiency and cost controls. Purity specifications directly influence regulatory acceptance, marketability, and consumer confidence, making rigorous analytical testing a central pillar of the manufacturing workflow.

Purified Sweetener products are often formulated with carriers, bulking agents, or excipients to achieve desirable handling properties, measuring characteristics, and compatibility with diverse product formats. Blended Sweeteners combine high-intensity Sweeteners with other components to achieve sugar-like bulk, improved mouthfeel, and tailored taste profiles for specific applications, such as beverages, baked goods, or pharmaceutical tablets. The formulation stage also considers stability under processing conditions (e.g., heat, shear, moisture) and compatibility with packaging materials. For OEM/ODM collaborations, formulation flexibility is a critical differentiator, enabling customized Sweetener solutions that meet unique brand specifications and regulatory requirements.

A rigorous QA/QC regime ensures product safety, consistency, and traceability from raw materials through finished goods. Analytical testing assesses purity, potency, impurity levels, pH, moisture content, and microbiological criteria where applicable. Documentation supports end-to-end traceability, enabling regulatory bodies to verify compliance with regional standards such as GMP, HACCP, and industry-specific guidelines. Regulatory compliance also encompasses accurate labeling, allergen declarations when applicable, and adherence to import/export requirements in target markets. Transparent QA/QC practices build brand trust and enable smoother market access for Sweetener-containing products.

The final Sweetener product must be packaged to protect against moisture, light, and temperature fluctuations that could degrade quality. Packaging formats range from bulk bags for industrial use to consumer-ready sachets, with attention to labeling accuracy and shelf-life claims. Storage conditions—controlled humidity, temperature, and segregation from incompatible materials—help preserve potency and sensory characteristics over the intended shelf life. Proper packaging also aids in safe handling during distribution, reducing cross-contamination risks in multi-product facilities.

- Food and beverages: Sweeteners enable reduced-sugar formulations while maintaining sweetness intensity, mouthfeel, and overall consumer appeal. They often allow product developers to meet calorie targets and cost considerations without sacrificing taste.

- Healthcare and pharmaceuticals: In chewables, tablets, and liquid formulations, Sweeteners improve palatability and patient compliance, particularly for pediatric or elderly populations. Regulatory considerations in these products include strict purity and safety standards.

- Nutraceuticals and functional foods: For dietary supplements and health-oriented foods, Sweeteners support low-calorie formulations while supporting product flavor and texture. Ingredient researchers balance taste profiles with compatibility with other actives, flavors, and packaging formats.

The Sweetener industry continually seeks improvements in process efficiency, energy use, waste minimization, and overall environmental footprint. Innovations focus on faster production cycles, lower solvent consumption, reduced emissions, and safer handling practices. In addition, mixed-blend Sweeteners, optimized for OEM/ODM projects, enable brands to tailor sweetness levels, aftertaste, and mouthfeel for diverse regional markets. The push toward sustainable sourcing and greener chemistry helps align Sweetener supply with broader corporate social responsibility goals.

Consumers increasingly demand transparency about ingredient sourcing, processing methods, and safety testing. Clear communication about what goes into a Sweetener, how it is produced, and how it performs in end products contributes to trust and brand loyalty. Companies in the Sweetener supply chain uphold privacy and IP protections while sharing enough information to satisfy regulatory and consumer expectations. Safety data sheets, batch records, and post-market surveillance programs form the backbone of ongoing consumer confidence.

Foreign manufacturers seeking Sweetener ingredients should consider:

- Supplier qualification practices and ongoing performance monitoring.

- Clear specifications for purity, impurity profiles, moisture, and pH.

- Stability data and packaging options suitable for regional distribution.

- Regulatory alignment across target markets, including labeling and safety requirements.

- Technical support, co-development capabilities, and flexible OEM/ODM arrangements to accelerate time-to-market.

A hypothetical case study demonstrates how a contract manufacturer can partner with upstream sweetener suppliers to deliver customized blends, tablet-ready formats, and finished goods for overseas brands. This example emphasizes quality controls, regulatory readiness, and efficient supply chains, highlighting how a strategic Sweetener program can reduce lead times and improve product consistency across regions.

A successful Sweetener operation maintains a culture of continuous improvement, with cross-functional teams focused on process optimization, safety, and customer satisfaction. Regular internal audits, supplier performance reviews, and cross-training programs help sustain high standards. This commitment translates into reliable supply for clients who rely on consistent Sweetener performance in their products.

As consumer expectations evolve, the Sweetener industry must adapt through responsible sourcing, cleaner production methods, and transparent communication. The ecosystem benefits from collaboration among farmers, researchers, manufacturers, brand owners, and regulators to deliver safe, high-quality Sweetener ingredients at scale. In this context, OEM/ODM collaborations become essential for delivering tailored Sweetener solutions that meet regional preferences while upholding global safety standards.

The production of a leading Sweetener involves intricate chemistry, meticulous purification, and careful formulation to deliver a sugar-like experience with reduced caloric impact. By maintaining rigorous quality assurance, transparent regulatory compliance, and a focus on sustainability, manufacturers can provide reliable Sweetener ingredients for diverse applications—from food and beverages to healthcare products. The integration of innovation and flexible collaboration models, especially for OEM/ODM partnerships, ensures that Sweetener solutions continue to meet evolving consumer expectations for taste, safety, and value in a connected, global market.

It involves transforming a carbohydrate into a high-intensity Sweetener with sugar-like bulk, followed by purification and formulation to achieve a safe, stable product suitable for various applications. This process emphasizes controlled reaction conditions and QA/QC at every stage.

Through strict process controls, purification steps, analytical testing, and adherence to GMP, ensuring that residual reagents and byproducts stay within regulatory limits.

Higher sweetness potency allows using smaller amounts to achieve the same level of sweetness as sugar, enabling calorie reduction and cost efficiency in final products.

Compliance with labeling, permissible ingredients, impurity thresholds, and safety evaluations varies by region; ongoing documentation and stability data support regulatory submissions.

Yes, formulations can be tailored to meet specific taste, texture, and dosing requirements for different product formats and client specifications, enabling seamless integration into finished goods.

[1](https://www.splenda.com/faqs/how-is-splenda-stevia-grown/)

[2](https://processengr.com/project/sucralose-sweetener-manufacturing-plant-preliminary-process-design/)

[3](https://ginhong.com/how-are-artificial-sweeteners/)

[4](https://easybuyingredients.com/blog/sucralose-production-demystified-from-raw-materials-to-manufacturing-process/)

[5](https://splenda-me.com/recipes/portfolio/how-is-sucralose-made/)

[6](https://www.splenda.com/faqs/what-is-splenda-sucralose-and-how-is-it-made/)

[7](https://www.sciencedirect.com/topics/food-science/sucralose)

[8](https://pmc.ncbi.nlm.nih.gov/articles/PMC3856475/)

[9](https://en.wikipedia.org/wiki/Sucralose)