Views: 222 Author: Sara Publish Time: 2025-11-23 Origin: Site

Content Menu

● The Industrial Production Process of Sucralose

>> Key Stages:

● Characteristics and Advantages of Sucralose

● Global and Chinese Market for Sucralose

● Environmental and Safety Profile

>> 1. What is Sucralose made from?

>> 2. Is Sucralose safe to consume?

>> 3. Can Sucralose be used in cooking and baking?

>> 4. Does Sucralose affect blood sugar?

>> 5. How does Sucralose compare to natural sweeteners like Stevia?

Sucralose is one of the most widely used artificial sweeteners worldwide. Known for being approximately 600 times sweeter than sugar, Sucralose has become a key ingredient in a myriad of products—from beverages and baked goods to dietary supplements and pharmaceuticals. This article delves into the origin, manufacturing process, properties, applications, and safety of Sucralose, with special emphasis on how it is produced and supplied by leading Chinese manufacturers, including our factory, which specializes in natural sweeteners, functional polyols, dietary fibers, and OEM/ODM services.

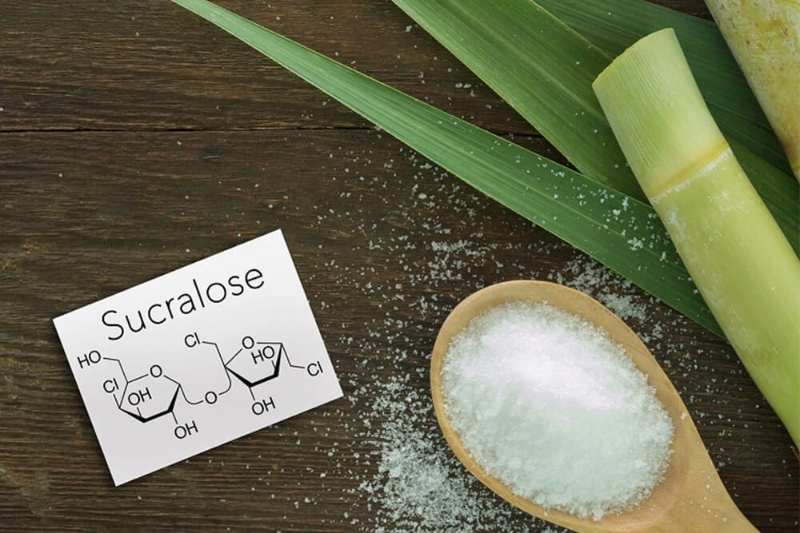

Sucralose is a zero-calorie artificial sweetener derived from sucrose (common table sugar). It is chemically modified to replace three hydroxyl groups in the sucrose molecule with chlorine atoms, resulting in a sweetener that tastes like sugar but is not metabolized for energy. This makes Sucralose a popular choice for reducing caloric intake without sacrificing sweetness.

Discovered accidentally in 1976 by British scientists seeking to develop novel sweeteners, Sucralose was found to have remarkable sweetness and stability due to chlorine substitutions on the sugar molecule. The combination of intense sweetness and zero calories quickly propelled its use in the food and beverage industries globally.

Sucralose production is a complex and highly controlled chemical process involving multiple stages. The primary industrial route used today is known as the single-group protection method, which employs selective chemical reactions to achieve targeted chlorination without damaging the sugar backbone.

1. Esterification to Form Sucrose-6-Acetate

The process starts with purified sucrose, which is transformed into an intermediate called sucrose-6-acetate via selective acetylation. This step uses dibutyltin oxide as a catalyst and takes place in a solvent like dimethylformamide (DMF), with acetic anhydride as the acetylating agent. Careful temperature (80-100°C) and pH control (around 8.5–9.0) prevent side reactions.

2. Chlorination Reaction

Using chlorinating agents such as a Vilsmeier reagent (a complex of DMF and thionyl chloride), three specific hydroxyl groups on the sugar molecule (positions 1', 4, and 6') are replaced with chlorine atoms. This step is conducted under inert nitrogen atmosphere at 60-80°C over 8-14 hours. Precise temperature control ensures complete and selective substitution while avoiding molecular degradation.

3. Alcoholysis (Deprotection)

The acetyl protective group is removed under mild alkaline conditions using sodium methoxide in methanol at temperatures between 20-35°C. This yields crude Sucralose.

4. Purification and Crystallization

Impurities and residual chemicals are removed via activated carbon treatment, ion exchange resins, and repeated filtration steps. The product solution is then concentrated through evaporation and subjected to controlled cooling with seeding to encourage uniform crystal formation. Final drying is achieved through spray or vacuum drying to obtain high-purity Sucralose powder.

5. Quality Control

Throughout the process, stringent monitoring of temperature, pH, chemical concentrations, and reaction times is conducted using advanced automated systems. Final product specifications include high purity (typically 99%+), particle size control, and microbiological safety.

This multi-step chemical synthesis, aided by specialized catalysts and enzyme-like reagents, enables cost-effective and scalable production of Sucralose. The process facilities in China, including our factory, utilize cutting-edge equipment designed to comply with international food-grade production standards.

- Calorie-Free: Sucralose passes through the digestive system without being metabolized, providing sweetness without calories.

- High Sweetness: At approximately 600 times sweeter than sugar, only small amounts are needed.

- Heat and pH Stability: Sucralose remains stable during baking, cooking, and in acidic or alkaline environments, making it versatile in diverse products.

- Water Solubility: Easily dissolves in liquids, enhancing usability in beverages.

- Long Shelf Life: Retains sweetness over time without degradation.

These qualities make Sucralose an ideal sugar replacement in products that require stability under heat and varying processing conditions.

While originally developed by companies in the UK and US, China is now a leading player in Sucralose production, supplying to global food, beverage, and healthcare manufacturers. Our Chinese factory is specialized not only in producing high-purity Sucralose powder but also in developing blended sweetener solutions tailored to clients' formulation needs. We provide extensive OEM/ODM manufacturing services including tablet production, ensuring consistency and top quality for export markets.

Sucralose's diverse properties enable its use in many food, beverage, and healthcare applications:

- Carbonated and flavored soft drinks

- Baked goods and confectionery

- Dairy products like yogurt and frozen desserts

- Nutritional and protein supplements

- Gum, throat lozenges, and oral care products

- Medicinal syrups and chewable pharmaceutical tablets

Its high sweetness, solubility, and stability under various conditions make it a preferred sweetening agent across industries seeking to reduce sugar content while maintaining taste.

Sucralose is approved for use by authoritative regulatory bodies including the FDA, EFSA, Health Canada, and China's NHC. Over 100 scientific studies confirm its safety for human consumption at approved levels. However, due to its chemical stability, environmental agencies continue to monitor potential ecological impacts from its presence in wastewater.

Sustainable manufacturing processes, involving solvent recycling and green chemistry principles, are adopted by forward-looking producers (including our factory) to minimize environmental footprint while delivering safe, high-quality Sweetener solutions globally.

Originating from common table sugar, Sucralose is transformed through a sophisticated process involving selective chlorination and purification steps into a uniquely sweet, calorie-free compound. Its remarkable sweetness, stability, and safety have made it indispensable in food, beverage, and pharmaceutical industries worldwide. As a leading Chinese manufacturer, our factory combines advanced technology and expertise to supply premium Sucralose and customized sweetener blends, supporting global partners with reliable OEM/ODM services.

Sucralose is synthesized from sucrose through a multi-step chemical process where three hydroxyl groups are replaced by chlorine atoms to create a non-caloric, intensely sweet molecule.

Yes, Sucralose has been extensively tested and approved by global regulations including the FDA and EFSA, confirming its safety for long-term use.

Absolutely. Sucralose is heat stable, allowing its use in baked goods and cooked foods without loss of sweetness.

No, Sucralose does not raise blood glucose or insulin levels, making it suitable for diabetics.

While both have zero calories, Sucralose has a sugar-like taste and better heat stability, whereas Stevia is plant-derived but can have a bitter aftertaste.

[1](https://www.bshingredients.com/sucralose-powder-99-manufacturing-methods/)

[2](https://easybuyingredients.com/blog/sucralose-production-demystified-from-raw-materials-to-manufacturing-process/)

[3](https://patents.google.com/patent/US7932380B2/en)

[4](https://processengr.com/project/sucralose-sweetener-manufacturing-plant-preliminary-process-design/)

[5](https://www.spectrumchemical.com/media/flowchart/Flowchart_S1416.pdf)

[6](https://www.sciencesnail.com/science/the-synthesis-of-sucralose-from-sucrose)

[7](https://www.spectrumchemical.com/media/flowchart/Flowchart_S1416.pdf?srsltid=AfmBOorQcFqG8neAUwgadOikse_p1sntq_TFIhxnzydzi0kxwvJlBi6H)

[8](https://www.sciencedirect.com/topics/food-science/sucralose)

[9](https://pdfs.semanticscholar.org/20ef/2df54580653c01409d6dedb6a85a73703bd8.pdf)

[10](https://en.wikipedia.org/wiki/Sucralose)