Views: 222 Author: Sara Publish Time: 2025-11-09 Origin: Site

Content Menu

● Deep Dive into Core Ingredients

● Regulatory and Safety Landscape

● Our Role as a Health-Solution Manufacturer

● Market Dynamics and Strategic Position

● Practical Implementation for Overseas Partners

● Sustainability and Social Considerations

● FAQ

>> 1. What is Splenda sweetener made from?

>> 2. Is Splenda considered a natural sweetener?

>> 3. How does Splenda behave in baking?

>> 4. Are there labeling requirements for Splenda in international markets?

>> 5. Can Splenda be combined with other Sweeteners or dietary fibers in a formulation?

In the landscape of modern food and beverage development, sweeteners play a pivotal role in enabling healthier formulations without compromising taste. This article explores what Splenda sweetener is made from, how it is produced, and what that means for manufacturers seeking reliable Sweetener solutions for global markets. It also highlights considerations for formulating with Splenda-like products, regulatory perspectives, and practical guidance for Food, Beverage, and Health-care applications in which a reliable Sweetener system is essential for product quality and consumer satisfaction. This extended version maintains a focus on your plant's capabilities in natural Sweeteners, functional polyols, and dietary fibers, and how blended Sweetener systems can be designed and produced through OEM/ODM partnerships for overseas manufacturers. The goal is to provide actionable insights for product developers, QA teams, and commercial partners looking to optimize sweetness, texture, and nutrition using sophisticated Sweetener formulations.

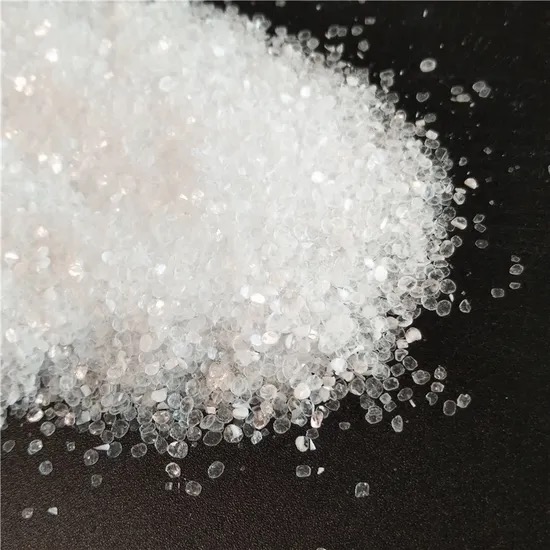

Splenda sweetener is widely recognized for its primary active ingredient, a high-intensity sweetener that delivers sweetness far beyond regular sugar. In many product formats, this sweetening agent is paired with carriers to create a practical, scoopable, and scalable Sweetener solution that fits into diverse manufacturing processes. Understanding the roles of these ingredients helps formulators tailor applications across beverages, bakery items, dairy, and nutritional products, while maintaining clean-label considerations and cost efficiencies. The combination of the intense sweetener and selected carriers defines not only sweetness level but also mouthfeel, dispersion, and stability on shelves worldwide. This section emphasizes how our health-solution factory can blend, customize, and optimize such Sweetener systems for overseas manufacturers.[9][10]

- High-intensity sweetening agent: The core sweetening component provides the bulk of sweetness, enabling reduced usage while achieving the desired taste profile. Its performance characteristics—such as sweetness intensity, onset, and aftertaste—are essential to predict how a product will perform in different formats. For developers, this means aligning sweetness with flavor clarity and product identity in a way that supports consumer acceptance across regions.[11][9]

- Carriers and bulking agents: In many formats, carriers like dextrose or maltodextrin serve multiple purposes: they improve handling and flow, provide bulk for dosing, and influence mouthfeel. Their selection and percentage can alter texture in baked goods, beverages, and confectionery, making precise formulation decisions critical for consistent results in manufacturing environments.[9][11]

- Formats and packaging: Splenda and its equivalents come in packets, granules, and other formats, each with a distinct carrier profile and performance envelope. Choosing the right format is a practical decision driven by equipment compatibility, product category, and consumer usage behavior.[11][9]

- Sensory profile: The interplay between sucralose (or analogous sweeteners) and carriers shapes sweetness perception, mouthfeel, and potential aftertaste. Formulators may use blending strategies with other Sweeteners to balance sweetness intensity and flavor cleanliness, particularly in dairy desserts, yogurt, and nutrition bars.[9]

- Heat and processing stability: In heat-processed products such as baked goods or hot beverages, understanding how the Sweetener responds to temperature, pH, and interaction with other ingredients is essential. Sucralose-based systems often exhibit favorable stability, but formulation must account for color development and flavor interactions during processing.[10]

- Solubility and dispersion: Uniform distribution of the Sweetener throughout liquids or powders influences batch consistency and consumer experience. Dispersion aids and formulation tricks—such as pre-dissolving in compatible carriers—can reduce clumping and ensure uniform sweetness in ready-to-drink products.[11]

- Regulatory status: Sweeteners like sucralose are approved in many regions as food additives or sweetening agents, with established usage limits and labeling requirements. Exporters should ensure compliance with destination-country regulations and keep thorough documentation for traceability.[10][9]

- Labeling considerations: Accurate nutrition panels and ingredient declarations support transparency and can meet consumer expectations for clean-label formulations. In some markets, disclosures about carriers can influence perceived healthfulness and product positioning.[9]

- Chinese factory strengths: The facility specializes in natural Sweeteners, functional polyols, and dietary fibers, offering blended Sweetener development, tablet production, and OEM/ODM services for overseas manufacturers. This positions the company to deliver customized Sweetener systems that meet taste, texture, and regulatory requirements while enabling scalable production for global brands. Emphasize capabilities in formulation optimization, quality assurance, and end-to-end manufacturing workflows.[12]

- Collaboration and customization: Our team can design tailored Sweetener blends that reduce sugar while preserving flavor profile and mouthfeel, integrating dietary fiber and polyol components as needed to meet nutrition targets or clean-label goals. Case-led discussions can showcase how to achieve sensory balance and manufacturing efficiency in beverages, bakery, and health-care applications.[12]

- Global demand trends: The market for low- and no-calorie Sweeteners continues to expand as consumers seek sugar reduction without sacrificing taste. For overseas manufacturers, partnering with a capable supplier for blended Sweetener systems and OEM/ODM services can facilitate faster time-to-market and more reliable supply chains.[12]

- Clean-label and natural trends: While synthetic high-intensity Sweeteners remain important for performance, there is growing interest in more natural or plant-derived options. A strategic portfolio that blends conventional Sweeteners with natural extracts or alternative sweetening systems can position a company for broader market access.[10][12]

- Formulation planning: Start with target sweetness level, texture expectations, and regulatory constraints. Use blended Sweetener systems to balance intensity with mouthfeel and reduce aftertaste, especially in dairy, snacks, and nutrition products. Document all ingredients, processing steps, and quality checks to support compliance.[12][9]

- Process integration: Consider equipment compatibility, thermal processing needs, and storage stability when introducing a new Sweetener system. Pilot runs can help refine carrier ratios, mixing sequences, and packaging formats to minimize waste and ensure product uniformity.[11]

- Quality and safety: Implement robust QA/QC protocols, supplier qualification, and batch traceability to align with international quality standards. Transparent quality records help build trust with overseas manufacturers and regulatory bodies.[12]

- Responsible sourcing: For plant-based or naturally derived components, sustainable sourcing practices add resilience to the supply chain and appeal to eco-conscious consumers. Communicate these practices clearly in product literature and with potential partners.[12]

- Health impact and consumer trust: Clear labeling, accurate nutrition information, and evidence-based claims support consumer confidence in Sweetener-based products. Ongoing monitoring and post-market feedback can guide iterative improvements in formulation.[9]

In today's global supply landscape, a robust Sweetener strategy is foundational for delivering tasty, low-sugar, and high-quality products. By leveraging blended Sweetener systems, your Chinese factory can offer tailored solutions that meet international standards, support OEM/ODM collaborations, and help overseas manufacturers achieve their formulation and regulatory goals. The emphasis on natural Sweeteners, functional polyols, and dietary fibers enables a versatile, scalable, and compliant Sweetener platform for a wide range of applications, from beverages and bakery to healthcare-ready nutrition products. This approach not only enhances taste and texture but also strengthens supply chain resilience and customer trust across global markets.

The primary sweetening agent is a high-intensity sweetener, typically combined with carriers like dextrose or maltodextrin in various product formats.[11][9]

Sucralose, the core component, is engineered and not derived directly from natural sugar in its final form, though it originates from sugar as a starting material in the chemical process.[4]

Sucralose-based sweeteners are generally stable under heat, allowing use in baked goods, though formulation may require careful balancing with carriers to maintain texture and browning.[5][10]

Yes, labeling must reflect sweetener content and carrier ingredients according to local regulations, with proper nutrition panels and ingredient declarations.[10][9]

Yes, blended Sweeteners with functional fibers or polyols can achieve sugar reduction with desirable mouthfeel and nutritional profiles, especially in health-oriented beverages and snacks.[12]

[1](https://www.splenda.com/faqs/how-is-splenda-stevia-grown/)

[2](https://ginhong.com/how-are-artificial-sweeteners/)

[3](https://easybuyingredients.com/blog/sucralose-production-demystified-from-raw-materials-to-manufacturing-process/)

[4](https://www.splenda.com/faqs/what-is-splenda-sucralose-and-how-is-it-made/)

[5](https://www.sciencedirect.com/topics/food-science/sucralose)

[6](https://processengr.com/project/sucralose-sweetener-manufacturing-plant-preliminary-process-design/)

[7](https://patents.google.com/patent/US4927646A/en)

[8](https://pmc.ncbi.nlm.nih.gov/articles/PMC3856475/)

[9](https://www.splenda.com/product/splenda-sweetener-packets/)

[10](https://en.wikipedia.org/wiki/Splenda)

[11](https://www.splenda.com/product/splenda-granulated-sweetener/)

[12](https://www.howtiangroup.cn/solutions-food)

Top Nutritional Supplement Manufacturers And Suppliers in Indonesia

Top Nutritional Supplement Manufacturers And Suppliers in India

Top Nutritional Supplement Manufacturers And Suppliers in Germany

Top Nutritional Supplement Manufacturers And Suppliers in France

Top Nutritional Supplement Manufacturers And Suppliers in Canada