Views: 222 Author: Sara Publish Time: 2025-10-28 Origin: Site

Content Menu

● How Splenda Is Produced (High-Level Overview)

● Sensory Profile, Application, and Performance

● Regulatory and Safety Context

● Implications for Blended-Sweetener Development and OEM/ODM

● Natural and Alternative Sweeteners Context

● FAQ

>> 1. What is Splenda made of and how is it produced?

>> 2. How does Splenda compare to sugar in sweetness and calories?

>> 3. Is Splenda safe to consume?

>> 4. Can Splenda be used in baking and hot beverages?

>> 5. How do natural Sweeteners fit into blended Sweetener strategies?

Splenda Sweetener has become synonymous with zero-calorie sweetness in modern kitchens and product formulations worldwide. As a leading Chinese factory specializing in natural Sweeteners, functional polyols, and dietary fiber, this piece explores what Splenda is made of, how its core ingredient is transformed, and what lessons can be drawn for blended Sweetener systems, tablet production, and OEM/ODM services. The narrative also situates Splenda within the broader landscape of Sweeteners, comparing chlorinated sugars with natural options like stevia and monk fruit, and with polyol-based systems that contribute body and mouthfeel to low-calorie formulations. The goal is to provide practical insights for manufacturers seeking scalable, high-quality Sweetener solutions across food, beverage, and healthcare applications.[9][10][11][12]

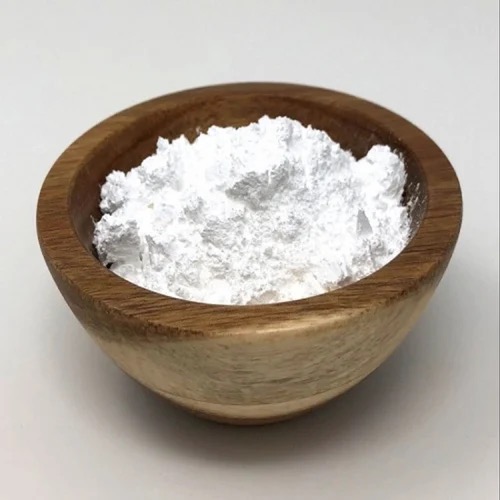

- Core ingredient: Sucralose. At the heart of Splenda is sucralose, a chlorinated derivative of sucrose that achieves extraordinary sweetness with minimal caloric contribution. Sucralose is approximately 600 times sweeter than sucrose and is largely not metabolized for energy, which underpins its near-zero-calorie labeling. The chemical modification blocks human digestive enzymes, allowing the sweetness to persist without energy contribution. This foundational chemistry informs many blended Sweetener strategies, where the intense sweetness of sucralose is balanced with bulk and texture agents.[10][13]

- Bulking carriers and formulations: To translate the intense sweetness of sucralose into usable formats, carriers such as dextrose and maltodextrin are commonly incorporated. These carriers aid in mouthfeel, smooth dissolution, and compatibility with a wide range of products—from beverages to baked goods. Depending on the product format, the carrier system can vary, influencing sweetness perception, calorie calculation, and label declarations.[11][9]

- Formats and variety: Splenda's portfolio spans packets, granulated blends, and baking-specific formulations. Each format leverages subtle differences in carrier content to optimize for dissolution speed, texture, and performance in hot or cold applications. This versatility is central to the global adoption of Splenda-inspired Sweeteners in diverse markets and product categories.[14][11]

- From sucrose to sucralose: The production of sucralose involves selective chlorination of the sucrose molecule, replacing three hydroxyl groups with chlorine atoms to yield a high-intensity sweetener that resists digestion. The resulting molecule provides intense sweetness with negligible caloric impact, enabling its widespread use in beverages, baked goods, dairy, and pharmaceutical aids. The production process emphasizes purity, safety, and compliance with food-grade standards.[13][10]

- Carriers and final formulations: In commercial Splenda products, sucralose is paired with bulking carriers such as dextrose or maltodextrin to create practical, scoopable products and stable blends for various applications. The final formulation is designed to balance sweetness intensity with mouthfeel and solubility, ensuring consumer satisfaction across different usage scenarios.[10][11]

- Quality assurance and regulatory alignment: The manufacturing and packaging of sucralose-based Sweeteners are governed by rigorous quality control processes and regulatory guidelines to ensure safety, consistency, and labeling accuracy. For OEM/ODM partners, understanding these standards helps in designing compliant blended Sweeteners and tablet formulations that meet international market requirements.[14][10]

- Taste and aftertaste: Sucralose delivers a sugar-like sweetness with minimal metallic or bitter aftertaste when properly formulated. This makes it particularly valuable for beverages, dairy desserts, and confectionery where flavor fidelity and mouthfeel matter. The sensory profile can be tuned by blending with polyols or natural Sweeteners to reduce any residual aftertaste in some consumer segments.[11][10]

- Heat stability and baking: Sucralose is known for relative heat stability, enabling usage in baked goods and hot beverages. Formulation strategies may include adjustments to moisture, browning reactions, and texture modifiers to preserve crumb and structure in bakery products, while still achieving sugar-like sweetness with fewer calories. This is especially relevant for OEM/ODM projects targeting bakery and snack categories.[10][11]

- Mouthfeel and body: When blended with functional polyols (like erythritol or sorbitol) and dietary fiber ingredients, sweetener systems can achieve a fuller mouthfeel and improved body, addressing common criticisms that zero-calorie sweeteners feel "thin" or "air-like." For health-focused products or clean-label desires, such blends can offer a compromise between palatability and label clarity.[12][10]

- Global approvals: Sucralose has undergone extensive safety assessments and has regulatory approvals in many jurisdictions as a safe food additive within established intake guidelines. This regulatory backdrop supports the broad adoption of Splenda-like Sweeteners in a wide array of foods and beverages. Keeping abreast of evolving guidelines is essential for manufacturers and OEM/ODM service providers who manage cross-border formulations.[11][10]

- Consumer trends and labeling: While many markets accept sucralose as safe, there is rising consumer interest in natural Sweeteners and cleaner labels. Blended Sweeteners that combine sucralose with natural options can address consumer demand for fewer synthetic notes while preserving sweetness, stability, and cost efficiency.[12][13]

- Customization and scale: For overseas manufacturers seeking turnkey Sweetener solutions, blending sucralose with carriers and natural Sweeteners allows tailoring of sweetness intensity, aftertaste, texture, and label claims. OEM/ODM capabilities can cover pilot formulation, sensory panels, stability testing, and scalable production to meet client specifications across beverages, nutrition bars, and pharmaceutical aids.[12][14]

- Ingredient interactions: Designing blends requires consideration of interactions with polyols (e.g., glycerol, xylitol) and dietary fibers to achieve desired mouthfeel, body, and stability. Clean-label positioning and regulatory compliance are important for market acceptance.[13][12]

- Tablet production and delivery formats: For tablet formulations, binders, disintegrants, and lubricants must be selected to maintain sweetness delivery, dissolution rate, and tablet integrity. This is an area where your OEM/ODM strengths can be highlighted, offering end-to-end solutions from formulation to packaging.[12]

- Stevia and monk fruit blends: In many markets, natural Sweeteners are favored for clean-label claims. Blending sucralose with stevia or monk fruit can deliver sugar-like sweetness with reduced aftertaste and a more natural label story, expanding application scope in beverages, dairy, and healthcare products. This approach aligns with consumer expectations for healthier choices while retaining product stability.[13][10]

- Polyol-based systems: Erythritol, xylitol, and sorbitol offer bulking, reduced-calorie contributions, and distinct mouthfeel. When used in combination with sucralose, these polyols can mitigate sweetness rebound and enhance astringency control, supporting a more balanced taste profile in complex products.[10]

Splenda stands as a benchmark in modern Sweetener technology: a highly intense, near-zero-calorie sweetener derived from sucrose through a chlorination process, paired with bulking carriers to achieve practical formats for mass-market use. For a Chinese factory specializing in natural Sweeteners, functional polyols, and dietary fiber, the Splenda framework offers concrete guidance on formulation accuracy, regulatory alignment, and market-driven product design. By integrating sucralose-based systems with natural alternatives such as stevia or monk fruit, and by exporting robust OEM/ODM capabilities for blended Sweeteners and tablet production, a manufacturer can meet diverse client needs—delivering high-quality, flavorful products at scale while maintaining transparent labeling and flexible customization.[11][10][12]

Splenda is primarily composed of sucralose, a chlorinated derivative of sucrose, produced by selectively substituting hydroxyl groups with chlorine atoms. The formulation often includes bulking carriers like dextrose or maltodextrin to enable practical formats such as packets or granulated blends.[9][10][11]

Splenda is roughly 600 times sweeter than sugar and contains negligible calories because sucralose is not metabolized for energy by the body, making it a popular sugar substitute for calorie-conscious consumers.[10][11]

Regulatory bodies have assessed sucralose as safe for consumer use within established intake guidelines; ongoing research and regulatory updates continue to monitor long-term effects and labeling considerations.[11][10]

Yes, sucralose is heat-stable enough for use in baking and hot beverages, though formulators may adjust moisture, texture, and browning elements to optimize product quality in different applications.[10][11]

Natural Sweeteners like stevia and monk fruit are often blended with sucralose to achieve a clean-label appeal, balanced sweetness, and reduced aftertaste. This approach supports diverse market needs and labeling requirements in OEM/ODM projects.[13][12]

[1](https://www.splenda.com/faqs/how-is-splenda-stevia-grown/)

[2](https://pmc.ncbi.nlm.nih.gov/articles/PMC3982014/)

[3](https://easybuyingredients.com/blog/sucralose-production-demystified-from-raw-materials-to-manufacturing-process/)

[4](https://www.sciencedirect.com/topics/food-science/sucralose)

[5](https://www.splenda.com/faqs/what-is-splenda-sucralose-and-how-is-it-made/)

[6](https://patents.google.com/patent/US4927646A/en)

[7](https://en.wikipedia.org/wiki/Sucralose)

[8](https://www.youtube.com/watch?v=GXI4_RANNBs)

[9](https://shoplocal.citarella.com/store/citarella/products/69475-splenda-sweeteners-zero-calorie-packets-50-ct)

[10](https://www.webmd.com/diet/what-to-know-about-sucralose)

[11](https://www.splenda.com/product/splenda-sweetener-packets/)

[12](https://www.caldic.com/zh-hans-cn/markets/food-beverage/beverage/)

[13](https://en.wikipedia.org/wiki/Splenda)

[14](https://www.splenda.com/product/splenda-granulated-sweetener/)